Supply Chain of the Plastic Straw

As a part of my MBA program, one of our assignments was to choose a product and break down the supply and access the sustainability components/implications that are caused as a result of the product. I chose the plastic straw.

The plastic drinking straw may be small but the supply chain is quite long and has a number of sustainability factors, both good and bad that should be considered:

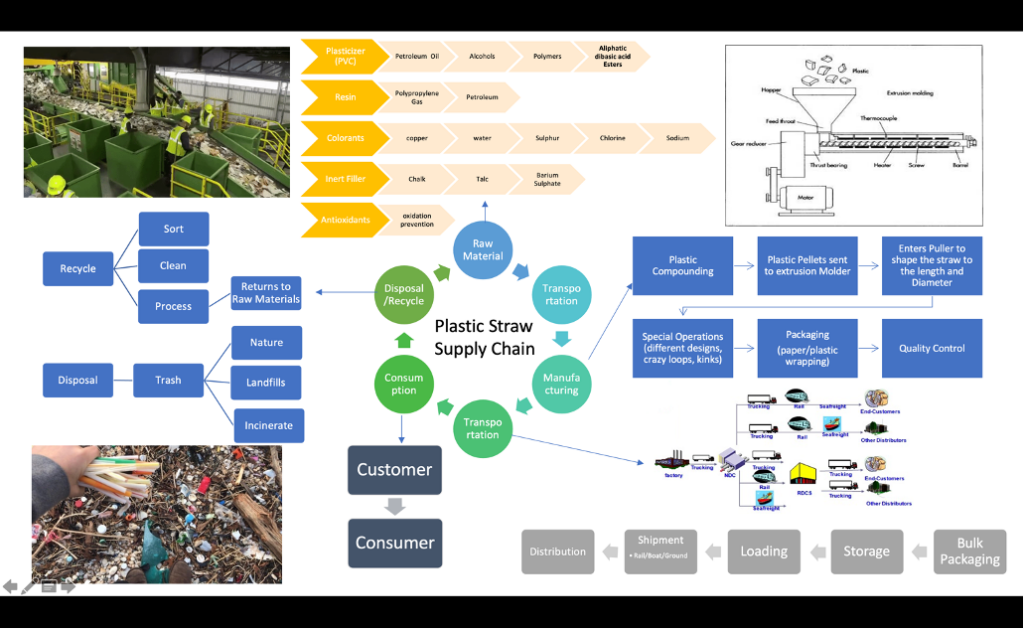

- Raw Materials: See Diagram for full list of materials

- Resin (Polypropylene)- FDA approved for indirect contact with food and drink [1] – is the polymerization of propylene gas. “The gas is extracted through standard oil extraction and then refined.” Fracking of crude oil and electricity to run the equipment [14]. Massive losses of energy because heating and cooling process (a lot lost in transportation of energy.)

- Plasticizer – FDA approved for indirect contact with food and drink [1] – These are a by-product of petroleum oil, alcohols, polymers, alipathic dibasic acid esters – Also known as PVC.[6] The purpose is to make the straw flexible. The PVC is created through chemical processing, the specific process used for the straw is the external, primary process. [7] Plasticizers are low-cost liquid formulations that react with alcohols and acids. They provide enhanced solvency, reduced viscosity, and augment lubrication [7]. More energy efficient to produce PVC then many plastic alternatives. [12]. But still uses large amounts of chemical and thermal energy [14]

- Inert Fillers – powdered Chalk, talc, barium phosphate [9] – mineral extraction required. Finite resources. Fossil fuel and electricity required to extract and produce

- Colorant – FDA approved [1] – colorants can be either organically or inorganically sources. Raw materials for pigments and dyes are a variety of chemical compounds, amino acids and water. In addition to chemical, there are metals and minerals: Copper, Sulphur, chlorine and sodium. [10] Environmental cost associated with the extractions of metals and minerals and combining of raw materials. Use of chemical and thermal energy [14]

- Antioxidant – compounds used to inhibit oxidation. Used as a stabilizer and lubricant. Prevent degradation of polymers [8]

- The equipment to produced or extract these raw materials uses fossil fuels and electricity – the whole process is extremely energy inefficient.

- Work place safety concerns. You have large machinery, high heat, and chemical reactions occurring throughout the entire process of extraction and production.

- Transportation: Part 1

- Sourcing local suppliers to help reduce costs and support the local community

- Fuel emissions -trucking/rail = air pollution, Ship = sea and air pollution

- Packaging of raw materials in plastics and cardboard generates waste

- Improper storage may impact quality of the raw material rendering the raw materials waste.

- All forms of transportation will be required given the nature of the product

- Manufacturing: See Diagram for Individual Stages in the process

- The mixing process occurs with all of the raw materials to create pellets for molding. Pellets are dried and stored until ready for mold process. Water waste to cool the water pellets [1]. Chemical reactions of mixing the all of the raw materials wastes significant amount of thermal and chemical energy [14]

- Pellets are packaged – packaging will become waste

- Fossil fuels/Crude Oils to run the machines to process together the raw materials

- Minimum Wages in production line set up

- Work place safety – working around large machines running constantly at high temperatures

- Energy/electricity costs to run maintain the factories that house the machines and the people

- Excess waste from scraps [1]

- Water Runoff waste from extrusion process [1]

- Noise pollution [2]

- Transportation: Part 2 – See Diagram for Individual stages

- Packaging items into customer packaging is extremely wasteful. There is excess plastic bubble wrap, package peanuts, cardboard boxes, tape, labelling, etc.

- Deforestation of trees for cardboard boxes, as well as the entire manufacturing process for the cardboard box.

- Chemical toxins created in the creations of tape/bubble wrap ect.

- Import/Export taxes/tariffs/paperwork required that could impact time in storage, impacting product quality

- Global distribution means no 1 specific mode of transportation and no one particular time frame, this can be extremely inefficient when trying to plan for new deliveries. Too much inventory could be wasteful and leaves excess, that sits in valuable storage space wasting money. Too little may cause shortage, hotel guests or bar patrons to complain and go elsewhere.

- Use of electricity for the packaging process.

- Consumption: Mass consumption

- Customer such as retail food chains, theme parks, etc, have the straws ready to use in their daily operations.

- The consumer receives the primary product with the straw included, and whether used or unused they discard product at end of primary products use. (some exceptions)

- Entire Consumption process is waste generating. Use requires little amount of consumer energy [14]

- Disposal/Recycle:

- It is no surprise that a majority of plastic straws end up in the garbage because usually they are used with a cup that isn’t recyclable, however the main reason is that plastic straws (basically) are too small to be recycled [3]

- No curbside recycling program will accept plastic straws in the US because they contaminate the and jam the recycling stream [4]

- It requires large levels of energy to recycle straws (if even accepted)

- Straw protective packaging is thrown away in garbage not recycled

- If the straws are accepted through recycling, the process still provides a significant amount of waste because any plastic resin that is “contaminated, overheated, or otherwise ruined must be discarded.” [1].

- The one benefit to the recycling of straws is that is can be done without losing its original quality.

- Incineration releases toxic chemicals into the air and into the ground. Chemicals remain for an estimated 400 years [5]

- Straws breakdown into microplastic which is easily digestible by wildlife [13]

Brief Thoughts on Mitigation:

- Eliminate the uses of all straws. Unless there are TRUE medical reasons for needing to sip a drink or food through a long tube, then there is truly no need to use a straw. Even then “reusable” straws are ending up in landfills, so unless the straw is fully biodegradable and the supply chain has a zero-waste footprint, this is a silly luxury/convenience item that the world could live without.

- Change materials used for existing straws. (bamboo, paper, sugar cane, straw, metal, pasta, glass, etc.)

- Use renewable energy as much as possible throughout the supply chain life cycle (transport, factory, recycling)

- Government regulations

- New taxes on straws – make the straws more expensive

- Required change of material on straws

- Banning of single use straws – for restaurants and purchasing in-stores

- Change the product design for the “To-Go” cups (a primary user of disposable straws)

- Enhance the recycling process/equipment to allow for straws

References:

[1] Schueller, Randy. N.D.A. How Products are Made. Drinking Straw. Retrieved on Feb 18, 2021. From: http://www.madehow.com/Volume-4/Drinking-Straw.html

[2] Green, Anna. June 3, 2016. Watch How Plastic Drinking Straws are Made. Retrieved on Feb 18, 2021. From: https://www.mentalfloss.com/article/81004/watch-how-plastic-drinking-straws-are-made

[3] Feltman, Rachel. Sept, 9, 2018. Plastic straws are little, but they are part of a huge problem

Retrieved on Feb 18, 2021: https://www.washingtonpost.com/lifestyle/kidspost/plastic-straws-are-little-but-they-are-part-of-a-huge-problem/2018/09/07/63bfe44e-ac9f-11e8-b1da-ff7faa680710_story.html

[4] Borg, John. N.D.A. What’s So Bad About Plastic Straws? Retrieved on Feb 18, 2021. From:https://www.steelystraws.com/sustainability/whats-so-bad-about-plastic-straws/

[5] Martinko, Katherine, Oct 11, 2018. How to Banish Plastic Staws From Your Life Forever. Retrieved on Feb 23, 2021. From: https://www.treehugger.com/how-banish-plastic-straws-your-life-forever-4853747

[6] Wadey, B.L. 2003. Plasticizer. Retrieved on Feb 23, 2021. From: https://www.sciencedirect.com/topics/chemistry/plasticizer

[7] Daniels, Paul. N.D.A. Selecting Plasticizers For Polymers. Retrieved on Feb 23rd, From: https://polymer-additives.specialchem.com/selection-guide/plasticizers

[8] Antioxidants. N.D.A Retrieved On Feb 23, 2021. From: https://en.wikipedia.org/wiki/Antioxidant

[9] Fillers. Rutlandplastics.co.uk Retrieved On Feb 23, 2021. From: https://www.rutlandplastics.co.uk/plastics-additives-intro/plastics-additives-fillers/

[10] Colorants. Retrieved On Feb 23, 2021. From: https://www.essentialchemicalindustry.org/materials-and-applications/colorants.html

[11] Polypropylene Chemical Compound. Encyclopedia Britannica. N.D.A. Retrieved On Feb 23, 2021. From: https://www.britannica.com/science/polypropylene

[12] ExxonMobile.com. N.D.A. Fundamentals of Plasticizers. Retrieved On Feb 23, 2021. From: https://www.exxonmobilchemical.com/en/products/plasticizer-story-campaign/fundamentals-of-plasticizers

[13] Tembopaper.com July 9, 2020. Plastic Straws and the Environment: What is the Impact? Retrieved On Feb 23, 2021. From: https://www.tembopaper.com/news/plastic-straws-and-the-environment-what-is-the-impact#:~:text=Plastic%20straws%20are%20not%20biodegradable&text=Instead%2C%20what%20happens%20is%20that,of%20up%20to%20200%20years.

[14] Downer, Anthony. Dec 6, 2018. Designlifwcycle.com. Plastic Straws. Retrieved On Feb 23, 2021. From: https://www.designlife-cycle.com/plastic-straws